XM Series Vibration Screen for the Mineral Processing Industry

Product Description

Cylindrical vibrating screen with eccentric shaft vibrator and partial block to adjust the vibration amplitude, material sieve line long, screening gauge grid, with structure can rely on, strong vibration force, screening efficiency.

High, vibration noise is small, firm and durable, maintenance and repair, safety and other features, The vibrating screen should be widely used in mining, construction materials, transportation, energy sources, chemical industry and other industries of product classification.

Anshan Qiangang XM series vibrating screens are designed to meet and exceed the demanding applications and specifications required of screening equipment, which provide a solution for all applications, including minerals, aggregates, etc. Each screen is built with maximum strength steel to withstand heavy loading and with the durability to provide you longer wear life.

Performance stable

The shafting is positioned on the heavy center to produce the whole body circular vibration track. Under the excitation force and the heavy force formed by the inclination Angle, the feed material moves forward along the whole screen surface with uniform speed.

Save energy and high efficiency

Adjustable setting to optimize screening efficiency and parameter setting wide range to achieve the best operational performance. The one-body feeding box is very wide and can be easily connected with the feeding belt. In addition, the feed box can also make the feed material evenly distributed on the whole width of the upper layer of the screen plate, and improve the screening efficiency.

Safety and convenience

The operating cost is low, the wear parts and spare parts benefit rate is high, the maximum range reduces the cost of high maintenance repair downtime.

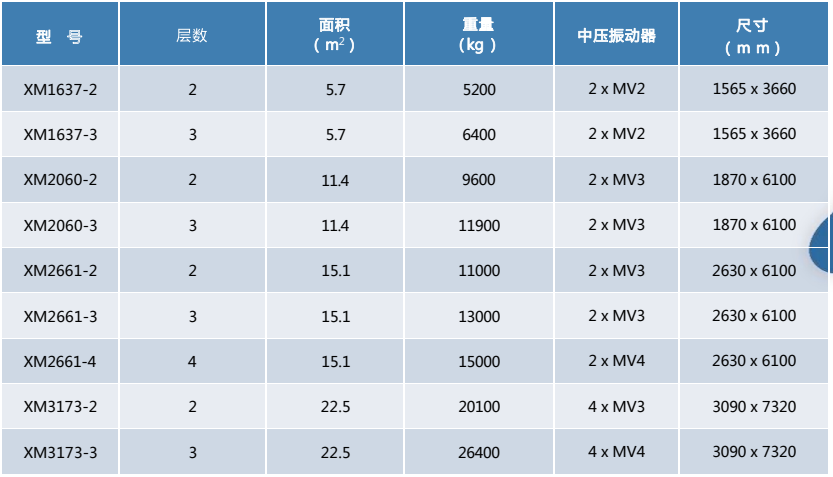

Product Parameter

According to technical changes and updates, the technical parameters of the equipment are adjusted at any time. You can directly contact us to obtain the latest technical parameters.