-

Multi Cylinder Cone Crusher Easy to Operate

QHP series multi-cylinder cone crusher is a multi-purpose rock crusher produced by Anshan Qiangang Machinery Manufacturing Co., LTD. It is often used in the crushing, fine crushing or ultra-fine crushing stage of sand and stone fields, quarries, metallurgy and other mining operations. Especially for high hardness ore crushing effect is better. Not only low wear and long service life, but also stronger bearing capacity. The structure is simplified, the volume is smaller, the weight is reduced by about 40% compared with the traditional spring crusher, and the operation cost is reduced.

Hydraulic control to adjust the discharge port, easy to operate, a variety of cavity shape adjustment accurate, saving time and effort.

-

Automation Control Single Cylinder Cone Crusher

QC series single cylinder cone crusher is a multi-purpose rock crusher produced by Anshan Qiangang Machinery Manufacturing Co., LTD. It is suitable for the crushing of raw materials in metallurgy, construction, road building, chemistry and silicate industries, and can break all kinds of ores and rocks above medium and medium hardness. Hydraulic cone breaking ratio is large, high efficiency, low energy consumption, uniform product particle size, suitable for medium and fine crushing all kinds of ore, rock. The bearing capacity is also stronger, the crushing ratio is large, and the production efficiency is high.

The hydraulic cone crusher adopts the special crushing cavity shape and lamination crushing principle to produce the crushing among particles, so that the proportion of the cube in the finished product is significantly increased, the needle flake stone is reduced, and the grain grade is more uniform.

-

CC Series Jaw Crusher Low Cost

Jaw Crushers are used to reduce the size of many different types of materials in many applications. They are designed to exceed the primary needs of customers in the mineral processing, aggregates and recycling industries. It’s consists of many parts such as an eccentric shaft, bearings, flywheels, swing jaw (pitman), fixed jaw, toggle plate, jaw dies (jaw plates), etc. A jaw crusher uses compressive force for breaking materials.

This mechanical pressure is achieved by the tow jaws dies of the crusher, one of which is stationary and other is movable. These two vertical manganese jaw dies create a V-shape crushing chamber. The electrical motor drives transmission mechanism driven swing hanging around the shaft relative to the fixed jaw do periodic reciprocating motion. The swing jaw undergoes two types of motion: one is a swing motion toward the opposite chamber side called a stationary jaw die due to the action of a toggle plate, and the second is a vertical movement due to the rotation of the eccentric. These combine motions compress and push the material through the crushing chamber at a predetermined size. -

XH Series Gyratory Crusher for High-Strength Production

XH gyratory crusher is match with the international advanced rotary crusher technology, is a new type of intelligent, high efficiency and large capacity of coarse crushing equipment. Integrate machinery, hydraulic, electrical, automatic intelligent control technology is equal to one. Compared with the traditional gyratory crusher, XH gyratory crusher has high crushing efficiency, low cost, convenient maintenance, and it can provide users with efficient and intelligent large capacity coarse crushing solutions.

-

Easy to Install and Lightweight Vertical Shaft Impact Crusher

The word impact makes sense that in this particular type of crusher some impaction is being used for crushing of rocks. In normal types of crusher pressure is generated for the crushing of rocks. But, impact crushers involve an impact method. The first Vertical Shaft Impact Crusher was invented by Francis E. Agnew in 1920s. They are designed to be used in secondary, tertiary or quaternary stage crushing. The crushers are suitable for a wide range of applications including the production of high-quality manufactured sand, well-formed aggregates and industrial minerals. Crushers can also be used for shaping or removal of soft stone from aggregate.

-

High Quality Jaw Crusher Spare Parts

Qiangang prides itself on offering an extensive range of wear and spare parts for cone crushers, jaw crushers and gyratory crushers. Our parts are engineered to increase crushing performance and avoid unplanned downtime. In addition, we also provide high-grade spare and wearing parts suitable Non-Qiangang crusher. Our parts embody OEM design principles and are crafted using extensive experience in mineral processing and aggregate production. You can rest assured that our crusher wear and spare parts will fit your machine precisely, provide excellent performance, and have an extended wear life. Learn more about our products by submitting your OEM part number and contacting us through our contact form. Join our mission to maximize your machine’s potential.

-

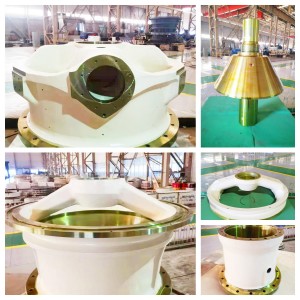

Multi-Cylinder Cone Crusher Spare Parts

Qiangang offers a wide range of wear and spare parts for cone crushers, jaw crushers and gyratory crushers. Our products are designed to enhance crushing performance, ensuring seamless operation without unplanned downtime. In addition, we also supply high-quality components for non-money steel crushers. These parts are engineered using original equipment manufacturer (OEM) technology and decades of mineral processing and aggregate production expertise. The perfect fit and long-lasting durability of our crusher wear and spare parts guarantee top-notch performance. For more details, simply fill out the contact form and include your OEM part number to see how we can further assist you.

-

Single-Cylinder Cone Crusher Spare Parts

Anshan Qiangang exceptional parts portfolio includes an extensive range of quality wear and spare parts for jaw crushers, cone crushers and gyratory crushers, delivering superior crushing performance with minimal to no unplanned downtime. Crafted to meet the exacting specifications of our customers, our components reflect our decades of experience in mineral processing and aggregate production. In addition, we also provide excellent OEM quality wear parts and spare parts for Non-Qiangang Crusher to best meet the different needs of all customers. Our parts are engineered to provide long-lasting wear life, ensuring superior performance and durability that exceeds your expectations. If you need further guidance on our products, please feel free to fill out our contact form and provide us with your OEM part number. Let us show you how to lift your machine to unrivaled heights.

-

Vibrating Grizzly Feeder Widely Used in Quarries, Recycling, Industrial Process, Mining, Sand and Gravel Operations

GZT Vibrating grizzly feeders are designed to combine the functions of feeding and scalping into one unit, reducing the cost of extra units and simplifying the crushing plant. Vibrating grizzly feeders are mainly used to feed a primary crusher in stationary, portable or mobile applications. The Vibrating grizzly feeders provides continuous and uniform feeding rate under a variety of loading and material conditions. Vibrating grizzly feeders are designed to absorb heavy shock of material loading. Vibrating grizzly feeders is widely used in quarries, recycling, industrial process, mining, sand and gravel operations.

-

XM Series Vibration Screen for the Mineral Processing Industry

Vibrating screens are the most important screening machines primarily utilized in the mineral processing industry. They are used to separate feeds containing solid and crushed ores, and are applicable to both perfectly wetted and dried operates at an inclined angle.

Vibrating screen, also known as circular vibrating screen, is a kind of circular vibrating screen, multi-layer number, high effect new type vibrating screen.